Overhaulin’ the King Tiger sprocket

Here we give a small summary about those features that we focused on, when design the new sprocket for the MENG KT.

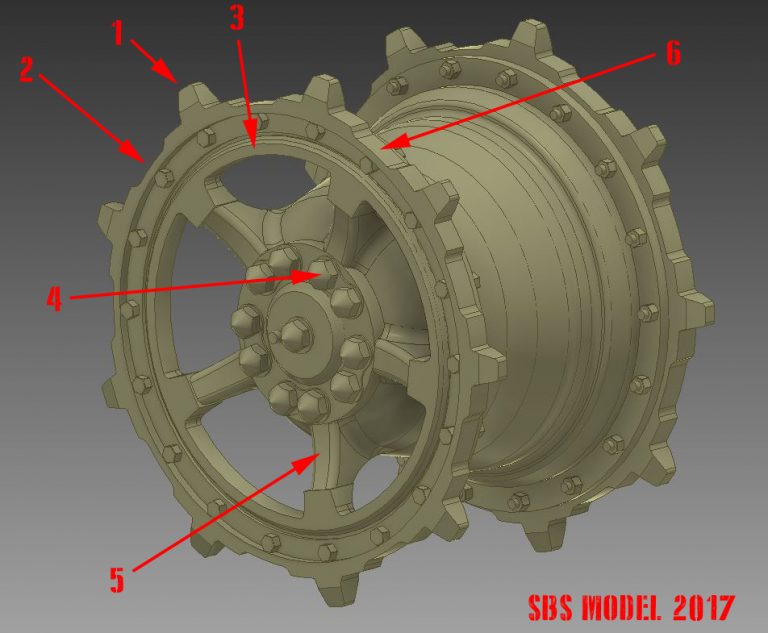

Type A: (Saumur, Bovington, Fort Knox, Kubinka)

1. reshaped teeth

2.stronger cut-outs in the intersection of the teeth, that allows to fit better the aftermarket metal tracks

3.stronger and chamfered inner rim, the outer surface raised up

4. repositioned bolts close to the the centerline of the spoke

5. reshaped, and refined casted outfit of the spoke with lowered center hub’s plate.

6. increased thickness of the ring with the teeth

7. increased thickness of the outer ring with bolts

8. longer legs for the spokes

Type B: (La Gleize, Full-Reuenthal)

Type B, as we call, is a reinforced(probably) version of the original production sprocket. This type of sprocket seen in several archive photos, but we cannot identify or connect to any other special features that changed in the production of the vehicle. Sometimes, for unknown reason both type were fitted, left and right sides mixed. Good examples for that the KT exhibited in La Gleize, from the former ss501, and the Swiss KT, that restored recently.

The main differences are with the type A:

1. stronger, cubic shaped casted spokes

2. Repositioned bolts in the center hub.

3. the extrusion in the center hub got vertical wall, not angled like in type A

No other differences identified by us during the engineering of the CAD model.

Fitting

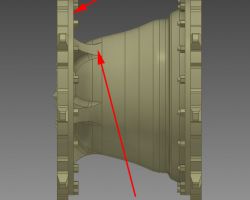

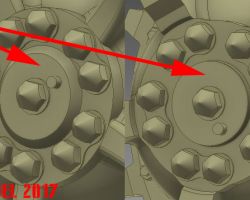

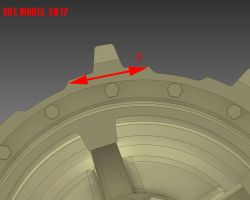

The original sprocket fits well, but when the tracks are applied, there is a problem turns up where the tracks contact the final drive’s curved armor. Despite the diameter is same in the new printed sprocket and the original, there is not enough under supporting, connection surface to keep the tracks in right position upwards. There is a hard contact between the armor and the tracks(pic no.1). We increased that area(see pic no.2) in the outer ring to keep the tracks away, and achive better looking of the tracks.

When we finished the design, and we were after several beer in our beloved pub, we figured out, the complexity of the new part’s shape force us to leave the common resin casting multiplication, and somehow we must release it in original printed condition.

Thanks for the attention, we hope we gonna meet soon in a pub, or in a competition!

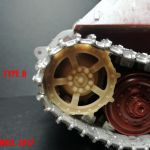

Some images about the test fitting

Leave a Reply to Koos van der Merwe Cancel reply

Send Email

Recent Posts

Recent Comments

- Sudesh on Overhaulin’ the King Tiger sprocket

- Roman on How to work with acetate canopies and windscreens – part one: glue

- Csaba on Overhaulin’ the King Tiger sprocket

- Koos van der Merwe on Overhaulin’ the King Tiger sprocket

- Vladimir Kafka on Spanish Civil War Caudron 600 in 1/72

3 Comments

Hi Lost a sprocket on my model where can i get a replacement set as above 1/35

http://www.sbsmodel.com 🙂

cool attention to detail!

Looking at the Saumur KT, it looks like there could even be the two type of spoke on the same sprocket.

If you have the panzerbasics dvd, have a look at picture

t2_ext_hull_tw_1479.jpg

regards,

Sudesh